Aluminum Electrolysis Condition Monitoring and Decision Support

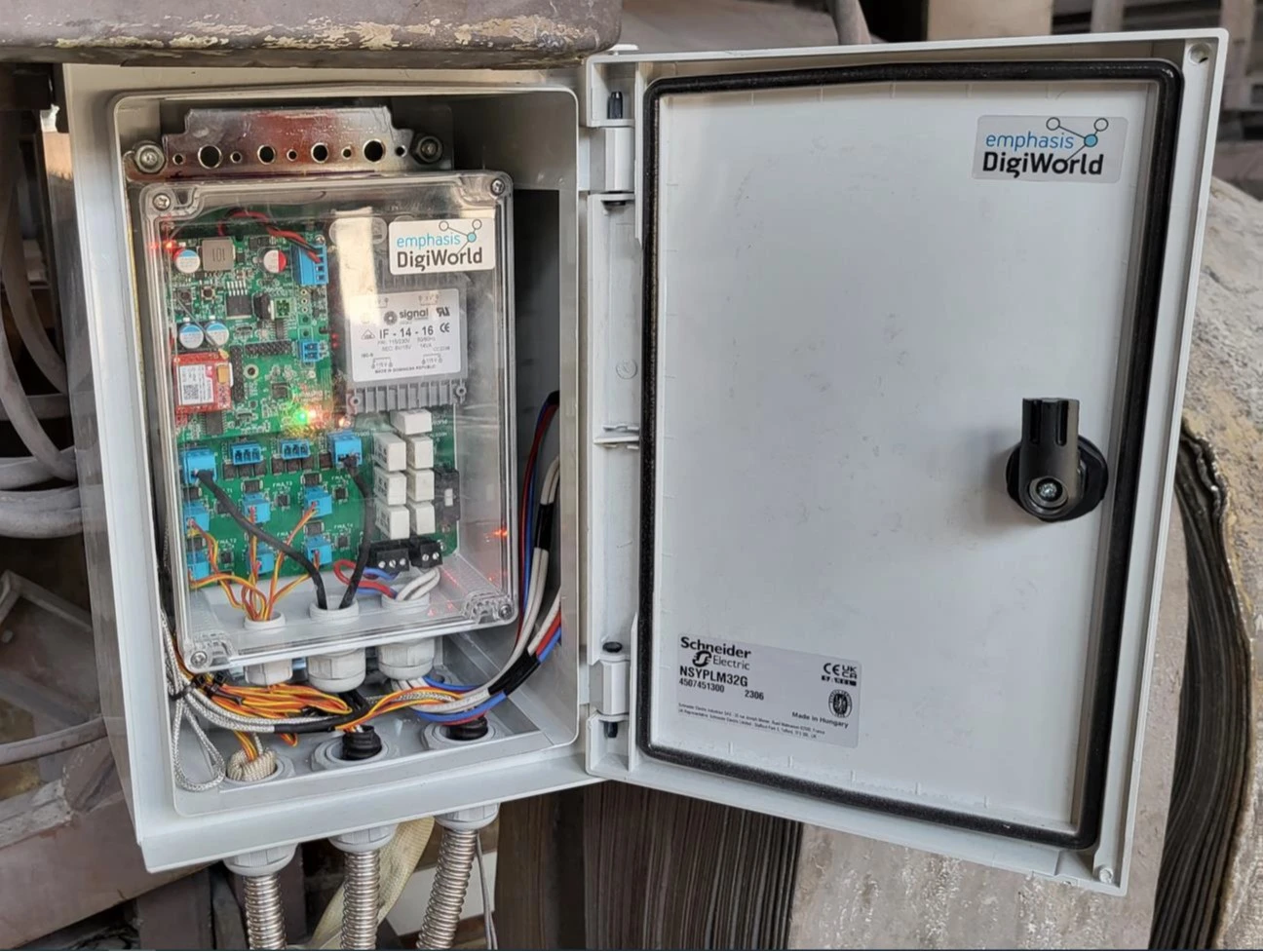

e-caisson is a next-generation Industrial IoT solution for the digitization and intelligent monitoring of electrolytic cells in aluminum production. By capturing and analyzing real-time process conditions, e-caisson provides end-to-end visibility of cell health, operator actions and production performance—supporting optimal operation, predictive maintenance and safer environments.

The Challenge

Electrolysis basins operate in extreme conditions, where the lack of real-time insight often leads to:

- Unplanned downtime and costly equipment wear

- Energy waste and suboptimal process control

- Safety risks for on-site operators

- Limited traceability of operational actions

The e-caisson Solution

e-caisson transforms electrolytic operations into data-driven, intelligent environments, monitoring and digitizing the entire workflow:

- Multi-point temperature sensing (up to 18 locations per basin)

- Sensor data on anode tension, vibrations, current per anode, immersion depth

- Optional monitoring of gas emissions (e.g. F₂ ppm)

- Operator Mobile App for real-time task tracking and digital workflow execution

- Integrated with AI/heuristic-based decision tools

- API-ready, syncing with enterprise IT infrastructure and cloud storage (e-meter)

Key Features

Digital Twin of the Electrolytic Cell

30–50 industrial sensors per basin

Automated Task Logging

Time-stamped records for operator activities

Mobile Work Assignments

Real-time tasking (e.g. raw material feeding, anode change, aluminum extraction)

Advanced Analytics & Alerts

Decision support for operational optimization

Energy Monitoring

Per-basin and per-series energy profiling

Environmental Compliance

Emissions tracking and process traceability

Benefits

Faster & better decision-making

Using both historical and real-time data with AI-backed decision tools.

Lower maintenance & asset costs

Early detection of wear or failure reduces operational expenses.

Energy savings

Optimize energy distribution and store surplus intelligently.

Sustainability

Reduce emissions and enable cleaner aluminum production.

Full operational traceability

Know what’s happening in every basin—every minute.